PRODUCTS INTRODUCTION

The series products are composed of acrylic resin, polyurethane resin, polyester resin, photoinitiator, reactive diluent, pigment, toner and additives. They exhibit low skin irritation, harmless discharge. Offset UV-LED curing ink is designed for printing on paper, metallized film, PET, PVC and so on. It is Sensitive to 365-405 wave light. They have perfect performances and are a kind of green ink.

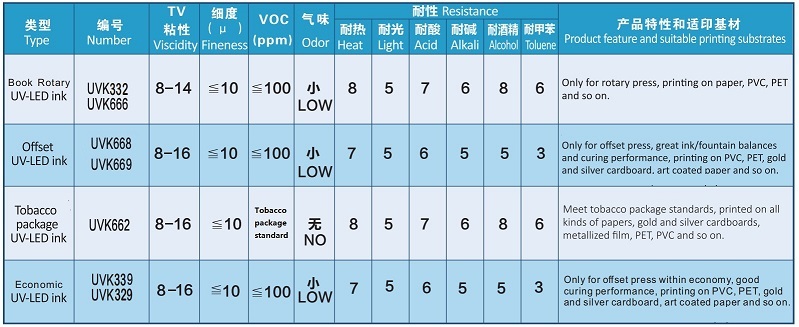

2.1 offset UV-LED ink product codes

2.2 product characteristics

l Operation performance: fast curing, good printing stability, excellent ink/fountain solution balance, clear points.

l Physical performance: good adhesion, high gloss, excellent abrasion and scratch resistance.

l Resistance performance: bright and high saturation color. Excellent heat, cold, acid, alkali and solvent resistance.

l Adaptability: printing inks for offset printing and water-free offset printing.

l speed: 6000-15000pages/h(single page offset)or 100-300m/min(rotary)

l curing energy(in 385nm): ≥500mJ/cm2

l reduce viscosity: with our company's specified reducer,max.3%wt

l Post-process: post process of UV offset LED ink is almost the same as solvent-based ink. But there are big differences with different substrates and post-process

materials, rigorous tests need to be used according to actual situation.

l Adhesion: rigorous tests need to be used according to actual situation because adhesion is big difference on different substrates, printing conditions, time and

surroundings.

l Storage conditions: The product should be stored in places safe from sunlight and excessive High temperature (>25℃) in original closed packages.

Copyright © 2017 Huizhou Prinstar Technology Co.,Ltd. 備案號(hào):粵ICP備17039748號(hào) Technical Support:HZWP Webmaster